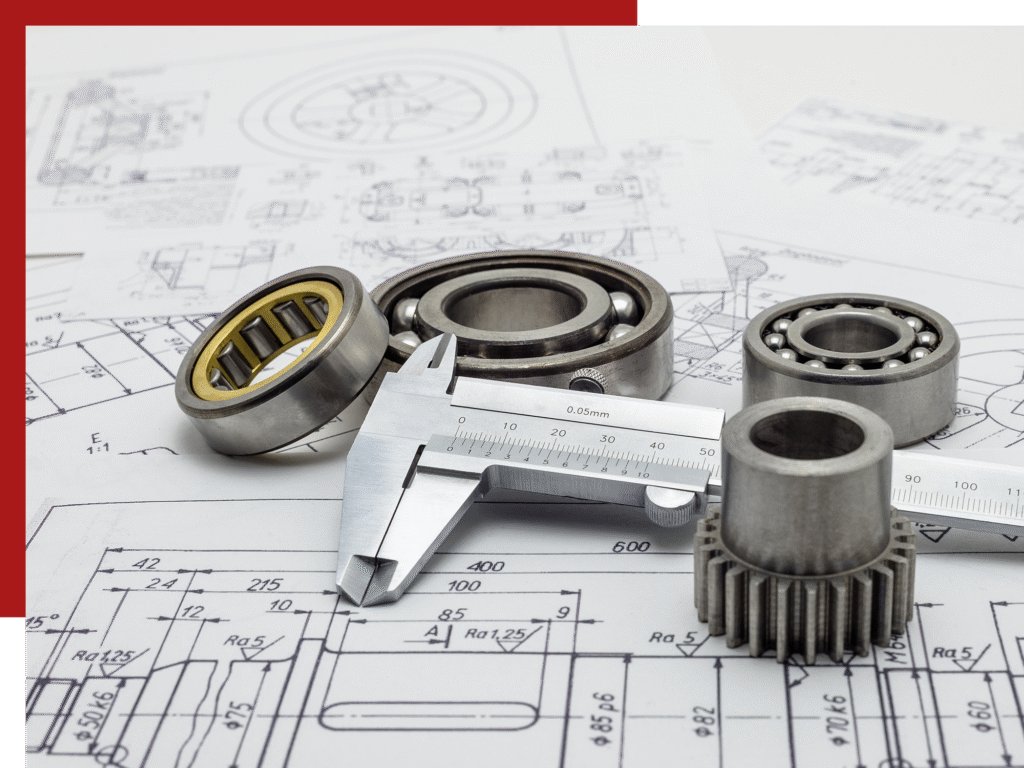

Design Solutions for Metal Products

At Metaline Industries, our design team turns your ideas into reality. We believe good design is not just about how something looks but how well it works. Our experts create smart, practical, and high-quality designs that meet your exact needs.

We use the latest tools and technology to bring your concepts to life. Whether you have a rough idea or detailed requirements, our designers work with you every step of the way to develop the perfect solution

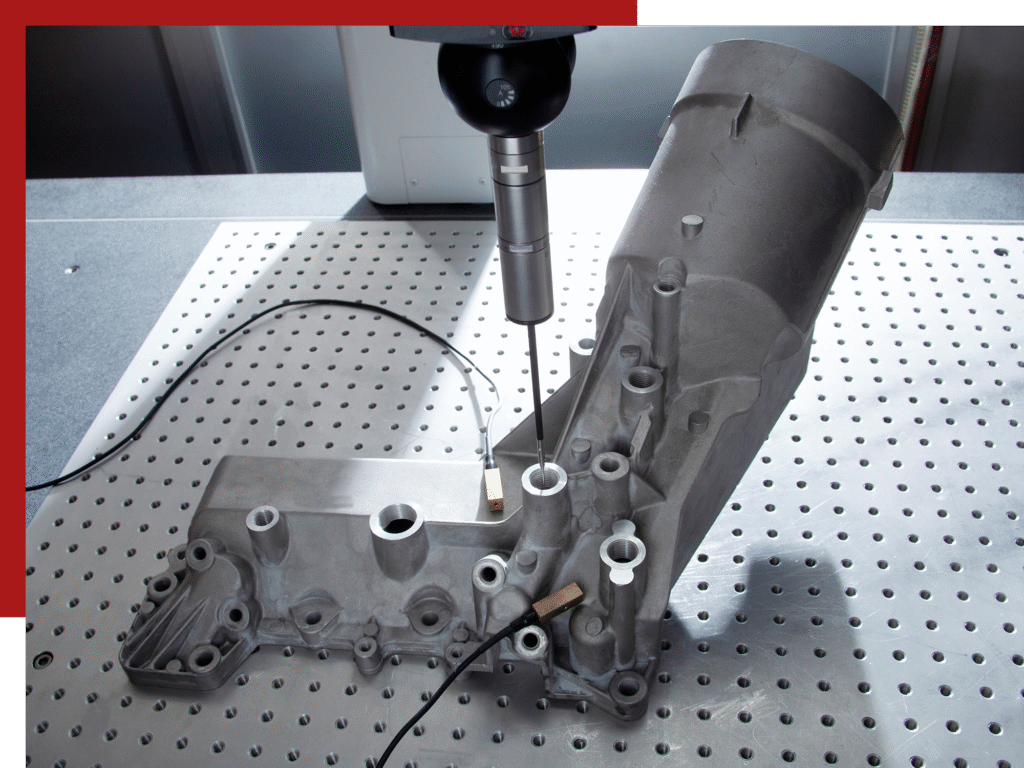

3D Scanning for Accurate Metal Inspection

We use advanced 3D scanning to ensure your metal parts are accurate and precise. Our portable CMM Arm captures detailed 3D scans, even for complex designs. With full movement, it covers every angle for quality checks and reverse engineering. This process ensures perfect fitment and reliable performance. It also helps reduce errors and speeds up production.

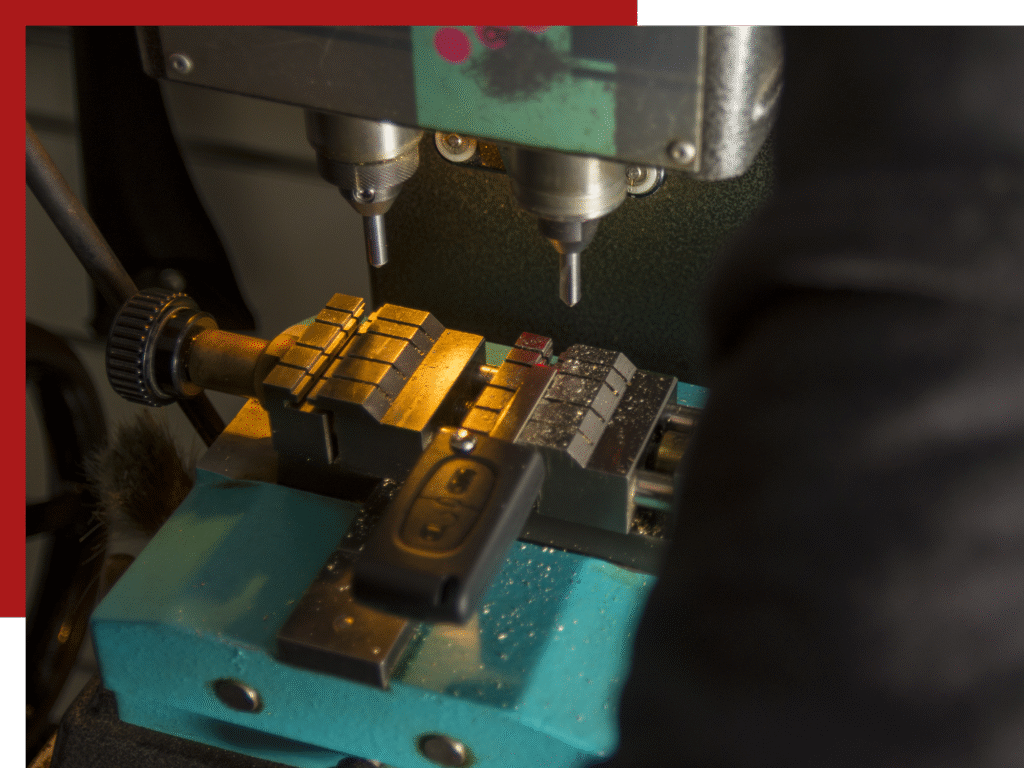

CNC Milling for Precise Metal Parts

We offer high-precision CNC milling for custom metal parts, tools, and dies. Our advanced machines work on X, Y, Z axes to create accurate parts, whether for small batches or large production. We handle complex shapes with speed and consistency. From prototypes to final parts, our skilled team ensures top quality and reliable results.

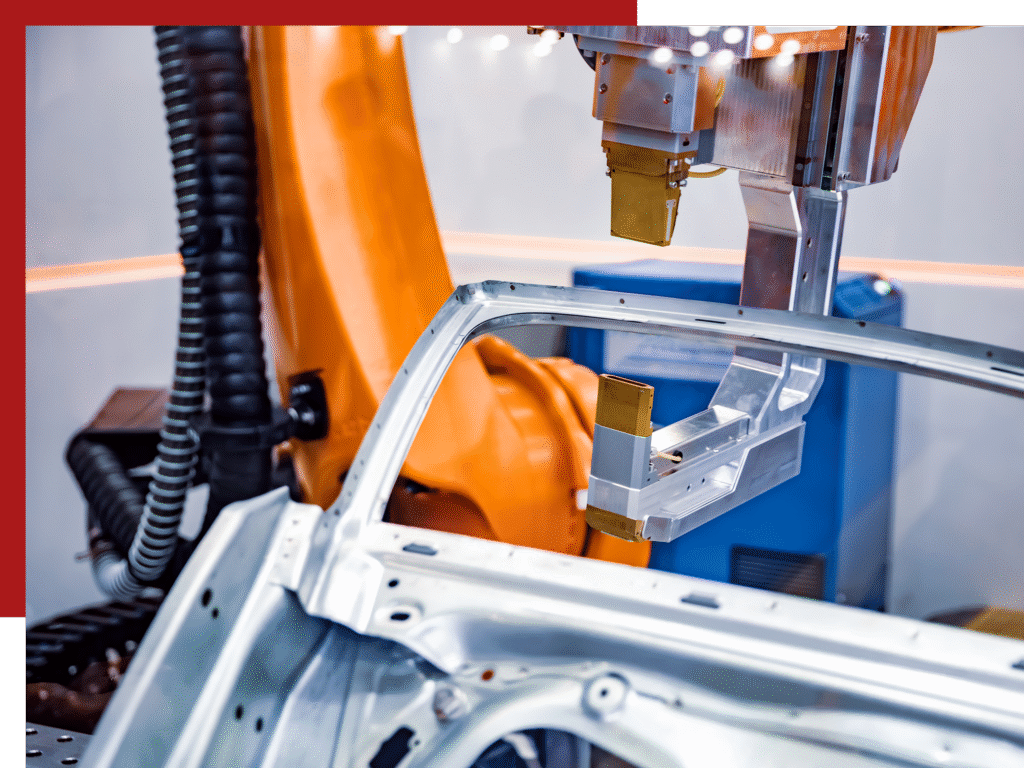

CHECKING GIGS AND FIXTURES

We use specially designed jigs and fixtures to check the quality and accuracy of our metal parts and dies. These tools help us make sure every part developed on our CNC machines meets the right measurements. Our stamped parts are also tested for perfect fitting and precision. To maintain high standards, we further verify everything using our advanced CMM Arm. This ensures every part is reliable and ready for use.

Die Fitting

Our die fitting process ensures exact alignment and smooth operation of tooling components for flawless production. Using precision techniques, we fit and adjust dies to match design tolerances, minimizing wear and maximizing efficiency. Whether for stamping, forming, or extrusion, we guarantee reliable setup and consistent performance in every cycle.

Do you want us to manufacture a part for you?

RAW MATERIALS

We use high-grade steel, aluminum, and stainless materials sourced from trusted global and local suppliers. Every batch is quality-checked to ensure consistency, strength, and suitability for industrial applications.

| Material | Grade | Common Use |

|---|---|---|

| Cold Rolled Steel | SPCC, CR1 | Body parts, stampings |

| Stainless Steel | SS304 | Exhausts, trims |

| Aluminum Alloys | 6061 | Lightweight fittings |

| Coated Sheets | GI, PPGI | Corrosion-resistant parts |

STAMPING

Our stamping unit supports high-volume production using both hydraulic and mechanical presses. This setup ensures efficiency, flexibility, and precision across various part sizes.

| Equipment Type | Quantity | Capacity Range | Daily Output | Bed Size Range |

|---|---|---|---|---|

| Hydraulic Press | 9 | 100 – 1000 tons | Up to 9,000 strokes/day | 450×450 to 1800×2500 mm |

| Mechanical Press | 32 | 15 – 500 tons | Up to 128,000 strokes/day | 300×300 to 1100×2400 mm |

Welding

We offer precision welding services for a variety of industrial applications. Using both MIG and TIG techniques, our welds ensure strength, durability, and clean finishes across mild steel, stainless, and aluminum components.

| Welding Type | Material | Application Areas |

|---|---|---|

| MIG Welding | Mild & Stainless | Frames, supports |

| TIG Welding | Stainless, Alu | Exhausts, delicate parts |

Paint

We offer high-quality industrial painting and powder coating services for lasting protection and finish. Our controlled environment ensures corrosion resistance, color accuracy, and durable adhesion for metal parts.

| Type | Finish Quality | Common Use |

|---|---|---|

| Powder Coating | Matte/Glossy | Frames, brackets, panels |

| Liquid Paint | Smooth/Custom | Body parts, custom components |

Company

Victor Auto Products is a trusted name in industrial manufacturing, delivering precision-engineered metal parts and solutions tailored to diverse industry needs. Quality, durability, and innovation define our work.

Quick Links

Contact

- 4 Montgomery Rd, Jogi Mohalla Garhi Shahu, Lahore, Pakistan

- © Copyright 2025 VAP